EU innovations

Smart Growth Operational Programme 2014-2020

Priority axis 3. Support for innovation in enterprises

Action 3.2. Support for the implementation of R&D results

Sub-measure3.2.2. Loan for technological innovations

Project title:

"Development of Wagran's product range through the implementation of innovative technology"

Financing agreement no. POIR.03.02.02-00-0490 / 16

Project description:

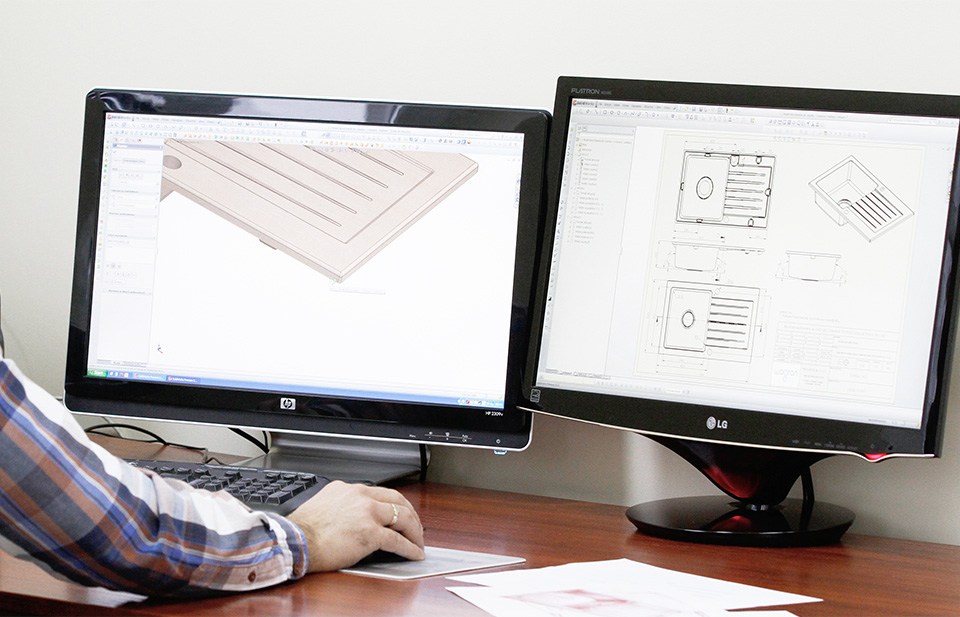

The main goal of the project is the implementation at Wagran of the wide-ranging results of the R&D work carried out by the Company, which resulted in the development of its own innovative production technology. As a result of its implementation, the production of a new family of bathroom and kitchen assortment, adapted to current trends and user requirements, will be started in relation to the ones currently produced on the territory of the Republic of Poland:

• hybrid kitchen sinks, bathroom sinks and shower trays,

• kitchen sinks, bathroom sinks (washbasins) and shower trays that can be made fluorescent and / or hydrophobic,

• bathroom sinks (washbasins) made of composite stone imitating natural stone, including reinforced with gelcoat,

• decorative hybrid heaters.

As a result of the project, a new production hall will be built, in which all machines and devices purchased as part of the project will be placed, forming a technological line for the production of the new assortment group. The implementation of this undertaking will positively affect the condition of Wagran. It will allow: - the Company to offer products with unique design, original geometry and properties, as well as to increase the variety of the offered range (shower trays, radiators), - to increase the company's competitiveness, increase its level of innovation, strengthen its market position and create the potential to build lasting market advantage not only in the country but also internationally, - increasing the production efficiency of models (compared to the current one), reducing its costs and reducing production time, - satisfying the identified expectations of customers, - increasing the company's flexibility, including its ability to react quickly for current product demand coming from the market. Therefore, the project contributes to the implementation of the main objective of the SG OP, the objective of measure 3.2 and sub-measure 3.2.2.

Total value of the project: PLN 16,568,000

Project co-financing from the EU: PLN 5,642,100