|

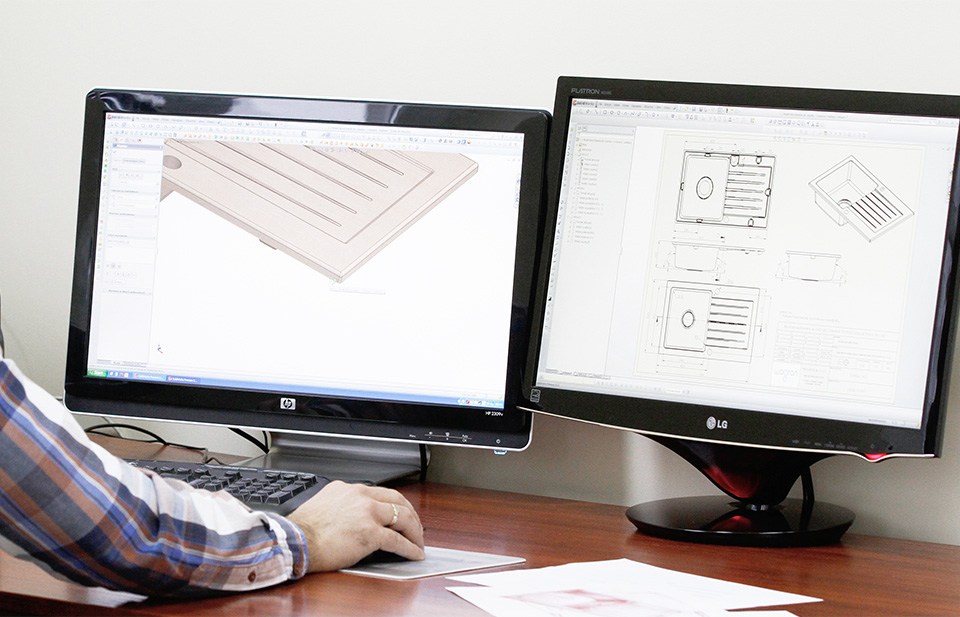

Form

|

Mounting type

|

Number of bowls

|

Dimensions of cupboard

under kitchen sink |

Type of draining board

|

|

Colour

|

||||